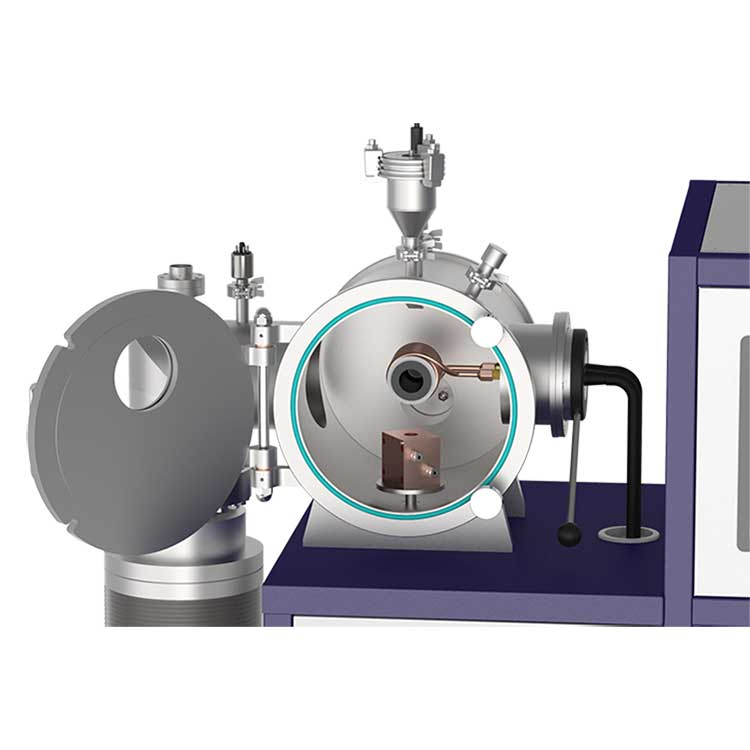

Heater material | Energy-saving tungsten mesh (purity 99%). The grid is connected to the electrodes. The transformer is connected to 3 electrodes through copper buses. The heating element, electrode and transformer form a control circuit with low power consumption. |

Thermal insulation of the furnace chamber | Made of 2 layers of tungsten (inner layer) and 7 layers of molybdenum (outer layer), connected by a SUS304 stainless steel holder. |

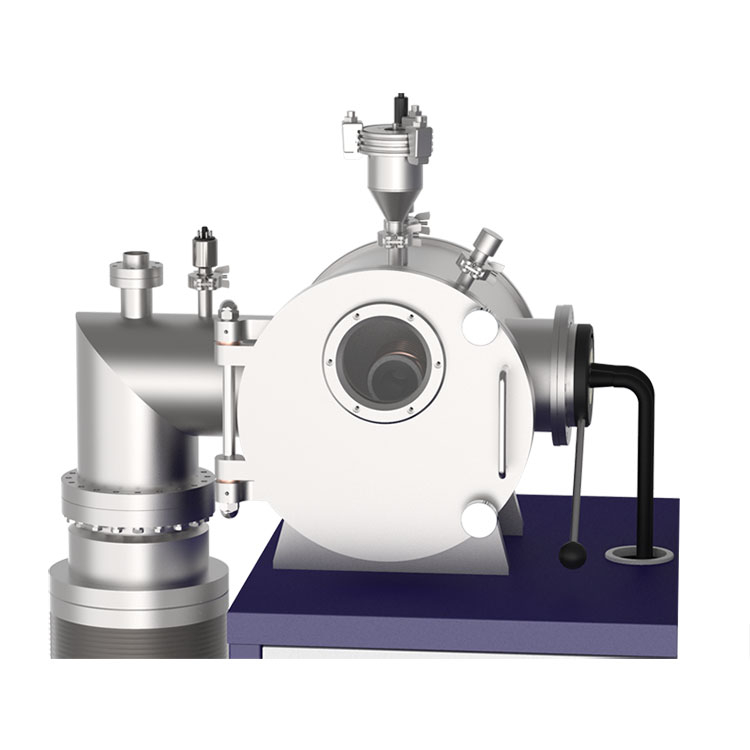

Oven lid | It has a two-layer stainless steel construction with built-in water cooling. The inner steel wall is polished to a mirror shine (class of surface treatment no lessD6). |

Water cooling system of the furnace body | The water cooling system consists of a system of pipes and taps, a system of light and sound emergency signaling and an emergency shutdown of the power supply. The stove is equipped with an intelligent water cooling device, which is used to cool the stove and related devices (water flow rate - 85 l/h, reserve water capacity - 155 l, cooling capacity 29.5 kW). |

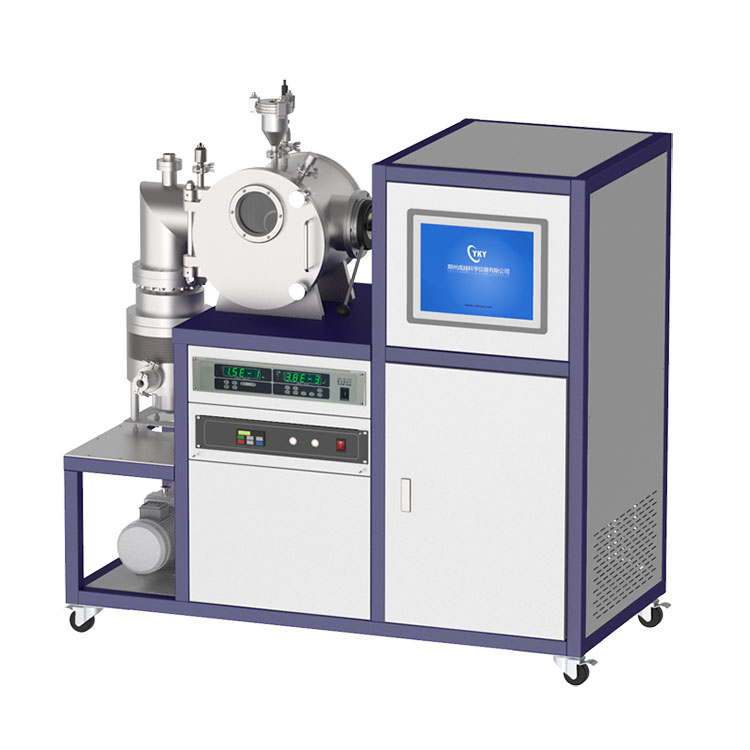

Vacuum system | The vacuum system consists of a plastic-rotor mechanical vacuum pump TRP-48 with a direct drive (pumping speed 14 l/s, maximum pressure 0.4 Pa); diffusion pump (pumping speed 2000 l/s, limit pressure 0.00007 Pa); vacuum shutter (Ø200 mm); inert gas inlet and outlet valves; vacuum filter; pneumatic low-vacuum cranes; composite vacuum gauge; stainless steel pipes. The furnace is equipped with a small air compressor that opens or closes the pneumatic valves. |

A means of monitoring the vacuum level | A composite vacuum gauge with a digital display is used to measure vacuum, which can provide continuous vacuum measurement (measurement range – 100000 Pa – 0.00001 Pa). |

Electric control system | The control system uses a low voltage high current transformer. Omron electrical components with high precision control are used. The electrical control cabinet is manufactured according to Rittal standards and is easy to operate. The electrical system is controlled using programmable logic controllers, the parameters are displayed on the touch screen. User can set temperature, vacuum and program by touching the screen. It is possible to save technological modes (temperature, vacuum and gas consumption). The current state of all parameters is displayed directly on the touch screen. Temperature control can be performed both automatically (thanks to the automatic PID control function) and manually according to user requirements. The system is equipped with the function of safe use, shuts off the power in case of overheating, when the water supply stops, has the necessary light and sound alarm and a mandatory emergency switch. |

Heater power supply system | Low voltage and high current transformer (converts 380V to 36V). |

Vacuum chamber opening system | The lifting device has a two-layer stainless steel structure with built-in water cooling. The furnace lid rises and falls with the help of a motor, which ensures convenient access to the camera. |